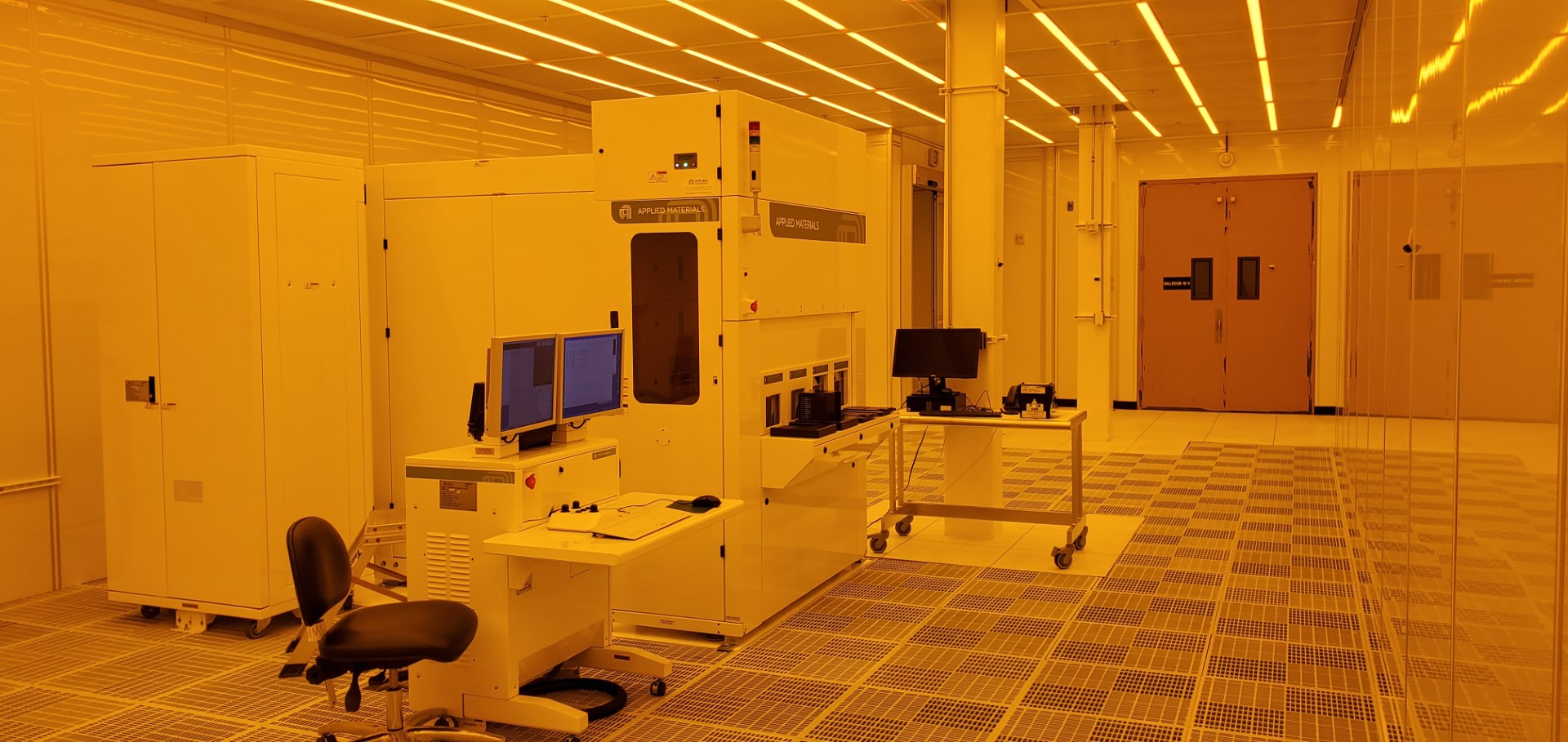

Cleanroom Expansion

Description

This semiconductor client needed to increase the capacity of its existing manufacturing facility. IPS was asked to modify and expand the existing cleanroom, install new semiconductor equipment, and upgrade their utilities. The existing area was demolished as IPS provided design-build services for new ISO-5 cleanrooms where the upgraded equipment was to be installed.

The project involved:

- demolition of all existing utilities to install newly upgraded versions

- installation of new electrical panels compliant to code

- demolition of existing concrete slab and excavation 5 ft below the floor to allow raised metal floor installation

- reinforcement of all columns to support additional loads

- reconstruction of the area for new ISO-5 cleanrooms.

The highly sustainable MEP systems include condensing water heaters, an ultra-high efficiency chiller plant, a condensing boiler heating hot water plant, a VAV lab exhaust system, a DI/RO water system, a VFD driven compressed air system, a lab vacuum system, and an LED-based high efficiency lighting and controls system. Controls include optimized chiller plant controls, integrated air and hydronic system optimization, and an energy dashboard for continuous performance validation.

IPS’s innovative safety processes led to zero incidents of significance on the project.

Project Details

LOCATION

San Jose, CA

MARKET

High Tech

PROJECT SIZE

4,900 sf

SERVICES

- General Contractor

- Construction Management

- MEP Design

KEY SYSTEMS

- Generator

- Diesel Tanks

- Pump Skid Systems

Company Profile

This corporation is known as one of the world’s largest computer hard disk drive manufacturers. With a decades-long history in the tech industry, the company serves clients, and their data management needs, worldwide.